In our previous article, we explored the base materials commonly used in bathroom cabinets, such as particleboard, MDF, plywood, and finger-jointed panels. In this guide, we focus on a more practical topic: bathroom cabinet surface finishing techniques. Choosing the right finish for a bathroom vanity is not only about aesthetics; it also impacts durability, moisture resistance, maintenance, and project suitability. Shouya, a leading bathroom vanity manufacturer, provides a professional overview of the most widely used bathroom cabinet finishes, including melamine-faced panels, PVC laminate, lacquered coatings, solid wood veneer, and electrostatic spraying from a B2B procurement perspective.

Bathroom Cabinet Surface Finishing Options Overview

A finish refers to the decorative and protective layer applied to the cabinet substrate. It affects visual attributes—such as color, texture, gloss, and tactile feel—as well as functional performance, including moisture resistance, scratch resistance, stain resistance, and ease of maintenance.

| Finish Type | Typical Substrate | Cost | Moisture Resistance | Durability | Style | OEM/Project Suitability | Key Pros & Cons |

|---|---|---|---|---|---|---|---|

| Melamine-faced panel | Particleboard / MDF / Plywood | Low | Medium | High | Modern / Commercial | ★★★★☆ | Pros: Durable, cost-efficient. Cons: Limited luxury appeal |

| PVC Laminate (Thermofoil) | MDF | Low–Mid | Medium | Medium | European / Classic | ★★★☆☆ | Pros: Flexible shapes. Cons: Sensitive to heat |

| Lacquered finish (PU) | MDF | Mid–High | Medium–High | Medium | Modern / Luxury | ★★★★☆ | Pros: Vibrant colors, smooth finish. Cons: Costly, prone to scratches |

| Solid Wood Veneer | MDF / Finger-jointed panels | High | Medium | Medium–Low | Natural / Premium | ★★★☆☆ | Pros: Authentic wood feel. Cons: Sensitive to humidity |

| Electrostatic spraying | Multiple substrates | Mid | High | High | Custom / Project / Commercial | ★★★★★ | Pros: Uniform coating, scalable. Cons: Requires advanced equipment |

Note: There is no universally “best” finish. The right choice depends on budget, project scale, usage environment, and supplier capabilities.

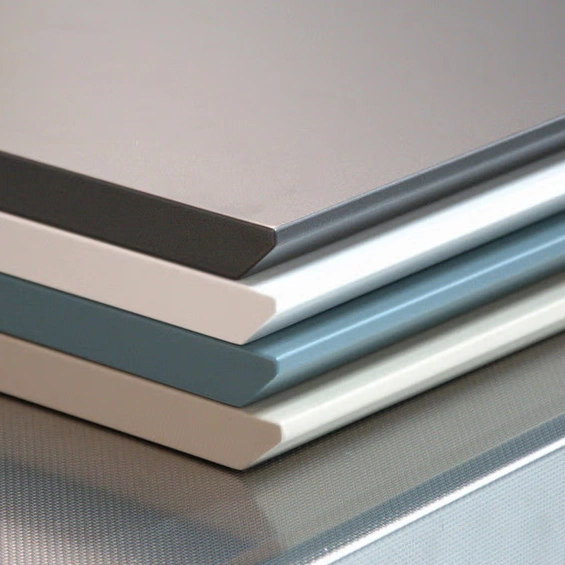

1. Melamine-Faced Panels

Melamine-faced panels are among the most common solutions in bathroom cabinets. Often referred to as “eco-friendly panels” or “paint-free panels,” they combine a decorative paper impregnated with resin and high-pressure lamination.

Advantages:

- Excellent resistance to wear, scratches, heat, acids, alkalis, and stains

- Low-cost and production-stable solution for OEM and project-based orders

- Advanced printing and embossing can replicate wood, stone, or metal textures realistically

Edge Banding Importance: Edge banding affects durability, moisture resistance, and environmental performance. Key factors include banding material, adhesive type (EVA or PUR), equipment precision, and process control. Shouya processes use laser edging, providing a tighter bond and cleaner appearance.

Shouya Procurement Tip: Best suited for large-scale projects or commercial OEM orders, especially where cost and consistency are critical.

PVC Laminate (Thermofoil) Finishes

PVC laminate, or thermofoil, is widely used in mid-range bathroom cabinets. The flexible PVC film is applied over MDF using heat and vacuum, allowing complex shapes and decorative profiles.

Advantages:

- Conforms to curved or molded door panels

- Offers texture depth and color consistency

- Good resistance to cracking, warping, stains, and fading

Limitations:

- Sensitive to high temperatures; avoid direct contact with hot objects

- Typically covers only the front and edges; fully wrapped six-sided panels increase cost

B2B Procurement Tip: Ideal for mid-range residential projects and classic European designs, but evaluate long-term performance in humid bathrooms.

Lacquered (Baked Enamel) Finishes

Lacquered finishes provide smooth, vibrant surfaces using spray application and high-temperature curing. MDF is commonly used to ensure flatness and stability.

Advantages:

- Multiple coating layers allow for color richness and surface smoothness

- Easy to clean, good moisture and fire resistance

- Premium options include piano lacquer and metallic finishes

Limitations:

- Higher cost and longer production cycle

- Surfaces are vulnerable to scratches and chips; repairs are difficult

Bathroom Cabinet Procurement Tip: Recommended for luxury or modern designs where visual impact is prioritized over cost.

Solid Wood Veneer Finishes

Solid wood veneers are thin natural wood sheets bonded to MDF or finger-jointed panels.

Advantages:

- Authentic wood appearance and tactile feel

- Natural grain variation adds premium aesthetics

- Suitable for high-end design-driven collections

Limitations:

- Lower moisture and fire resistance

- Sensitive to humidity and temperature fluctuations

- Higher cost, requiring careful handling and storage

Bathroom Vanity Procurement Tip: Best for premium, design-focused collections rather than large-scale projects.

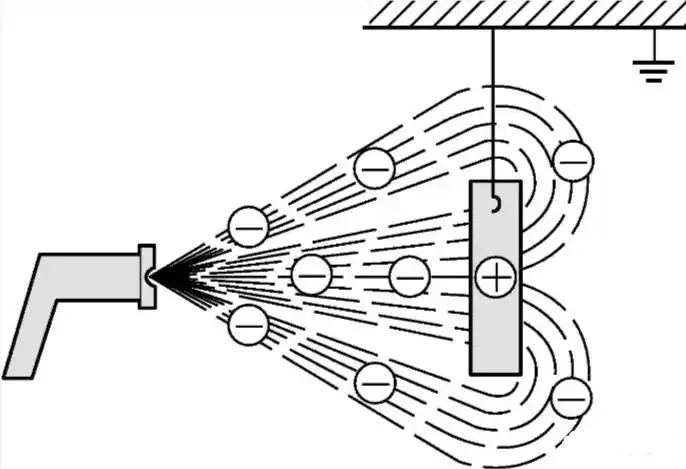

Electrostatic Spraying

Electrostatic spraying charges paint particles to achieve uniform coverage on grounded surfaces. This advanced process improves coating consistency, efficiency, and environmental performance.

Advantages:

- High-quality, uniform coatings on complex surfaces

- Scalable for large production runs

- Enhanced long-term performance and reliability

B2B Procurement Tip: Suitable for custom, project-based, and commercial orders where finish quality and process stability are critical.

About Shouya, Leading Bathroom Cabinet Manufacturer

Regardless of finish type, long-term performance depends on process consistency, quality control, and edge banding precision. Factors such as coating thickness, curing stability, adhesive quality, and environmental testing play decisive roles.

As a professional bathroom cabinet supplier, Shouya focuses on scalable, moisture-stable bathroom cabinet surface finishing solutions—including laser-edged melamine panels, electrostatic spraying, and carefully selected veneer systems—optimized for bathroom environments. Our processes support OEM, ODM, and project-based orders with consistent quality and controlled lead times.

Conclusion

This guide provides a professional overview of common bathroom cabinet surface finishes. There is no single “best” finish; the right choice balances budget, design intent, usage environment, and supplier capabilities.

Key Takeaways for B2B Purchasers:

- Evaluate the supplier’s process stability, edge banding quality, and production consistency

- Consider environmental conditions and long-term maintenance needs

- Match finish type to project scale and style requirements

- Shouya offers customized bathroom vanity OEM/ODM solutions, ensuring reliable finishes for commercial, residential, and high-end projects

Shouya provides a full range of bathroom vanities wholesale that are compatible with various bathroom cabinet surface finishes. Welcome to contact us for samples, technical specifications, and project-based consultation to ensure the bathroom cabinets project meets both aesthetic and functional requirements.