Lors du choix d'un armoire de toiletteLa plupart des gens se concentrent sur l'apparence, le style, la couleur et le design. Mais en tant que fabricant d'armoires de toilette qui a vu des milliers d'installations, je peux dire en toute confiance : La durabilité réelle d'un meuble de salle de bains dépend du matériau du panneau que vous ne voyez pas.

Si l'armoire était une personne, la quincaillerie serait les articulations, le design serait les vêtements et le matériau du panneau serait les os. Comprendre les "os" vous aide à choisir une armoire qui reste stable et sûre même après des années d'humidité, de changements de température et d'utilisation quotidienne.

Ce guide présente les principaux types de panneaux à base de bois utilisés dans les armoires de salle de bains, leur composition, leurs performances et les endroits où ils conviennent le mieux. À la fin, vous saurez exactement quel matériau répond à vos besoins.

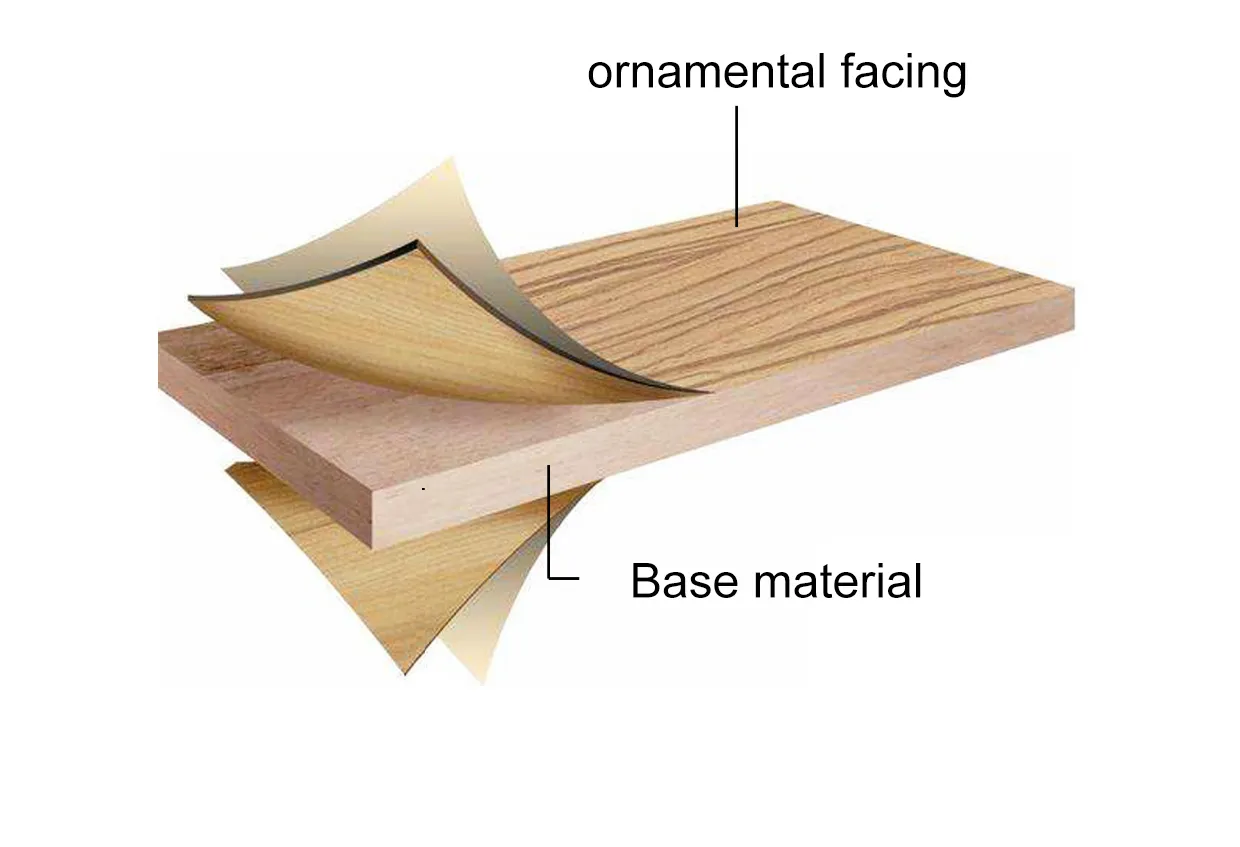

1. Comprendre Matériaux de l'armoire : Noyau + surface

Les "matériaux" des armoires de toilette se composent de deux parties :

- Le cœur (panneau de base)

- L'état de surface

Cet article se concentre sur la panel de baseElle détermine la stabilité, la solidité, la durabilité et la résistance à l'humidité de l'armoire.

Les noms courants des panneaux peuvent être très nombreux : contreplaqué, panneau multicouche, MDF, OSB, panneau de particules, panneau de fibres, panneau mélaminé, panneau écologique, etc. Mais ils peuvent tous être regroupés en plusieurs grandes catégories.

2. Principaux types de panneaux pour armoires de salle de bains

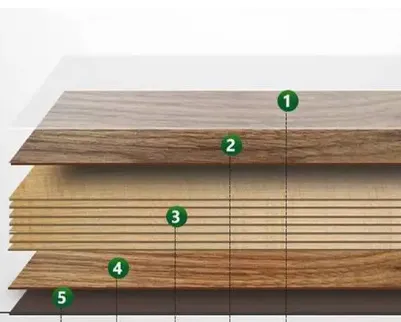

2.1 Panneau multicouche (contreplaqué / panneau multicouche en bois massif)

Également appelé :

- contreplaqué

- panneau en bois massif multicouche

- Contreplaqué de bois dur (HWPW)

Structure

Comme dans un gâteau à étages, les placages de bois sont collés dans des directions alternées et pressés à chaud.

Cette structure alternée donne au panneau :

- excellente résistance à l'humidité

- une force équilibrée

- performance stable

Spécifications

Taille standard : 1220 × 2440 mm

Épaisseur courante : 3 / 5 / 9 / 12 / 15 / 18 mm (les corps d'armoires utilisent généralement 18 mm)

Pour

- Très bonne résistance à l'humidité

- Forte stabilité structurelle

- Grande force de maintien des clous

Cons

- Les adhésifs varient considérablement, ce qui a une incidence sur les performances environnementales

- La qualité dépend fortement de la fabrication

Convient pour :

Corps d'armoires de salle de bains, armoires de cuisine et environnements humides.

2.2 Panneaux de particules (panneaux de particules / panneaux de particules en bois massif)

Il s'agit de l'un des matériaux en bois d'ingénierie les plus utilisés à l'échelle internationale.

Structure

Les copeaux et la sciure de bois sont mélangés à des adhésifs et pressés pour former des panneaux.

La qualité varie de très faible à très élevée, en fonction de.. :

- qualité des fibres de bois

- type d'adhésif

- technologie de pressage

Pour

- Bonne performance globale

- Structure stable, densité interne uniforme

- Surface lisse convenant aux stratifiés

- Bon rapport coût-efficacité

Cons

- Résistance modérée à l'humidité

- Capacité de fixation des clous inférieure à celle du contreplaqué

- Le fraisage est plus difficile

Convient pour :

Corps d'armoires dans les zones à humidité modérée, armoires à surface stratifiée.

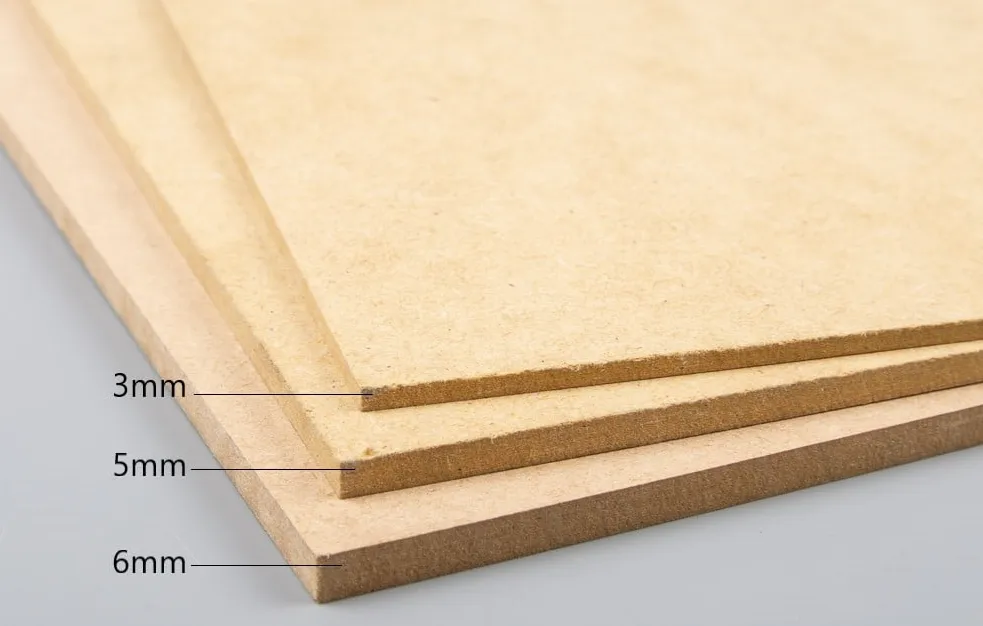

2.3 MDF (panneaux de fibres de densité moyenne)

Fabriqué à partir de fibres de bois finement broyées + teneur plus élevée en adhésif.

Pour

- Surface très lisse

- Idéal pour les portes d'armoires peintes ou sculptées

- Facile à façonner et à usiner

Cons

- Très mauvaise résistance à l'humidité

- Gonflement ou déformation sous l'effet de l'humidité

- Pas assez solide pour les corps de meuble

- La capacité de rétention des clous est faible

Convient pour :

Cabinet portes (notamment sculptées ou peintes), mais ne convient pas pour les cabinets ministériels.

2.4 OSB (panneau de lamelles orientées)

Une nouvelle génération de bois d'ingénierie avec des lames de bois directionnelles.

Structure

- Longs brins de bois empilés dans le sens de la longueur

- Couches externes orientées dans le sens de la longueur

- Couche intérieure orientée transversalement

Cela permet d'obtenir une stabilité dimensionnelle exceptionnelle.

Pour

- Excellente résistance à l'humidité et à l'eau

- Haute résistance et forte capacité de maintien des clous

- Très stable sous l'effet des variations d'humidité

- Presque tous les avantages du contreplaqué

Cons

- Surface plus rugueuse

- Options de couleurs et de finitions limitées dans la plupart des usines de fabrication de meubles sur mesure

Convient pour :

Environnements de salles de bains à forte humidité, corps des armoires et composants structurels.

2.5 Panneau de bois (panneau à âme en bois / panneau de menuiserie)

Un cœur en bois massif stratifié avec du placage.

Pour

- Grande rigidité

- Bonne tenue des clous

- Facile à usiner

- Bonne isolation acoustique et bonne rétention de la chaleur

Cons

- Mauvaise résistance à l'humidité

- Déconseillé pour les cuisines et les salles de bains

- La qualité varie fortement selon l'essence de bois

Convient pour :

Armoires, portes et cloisons pour locaux secs -pas idéal pour les salles de bains.

2.6 Panneau abouté (panneau en bois massif)

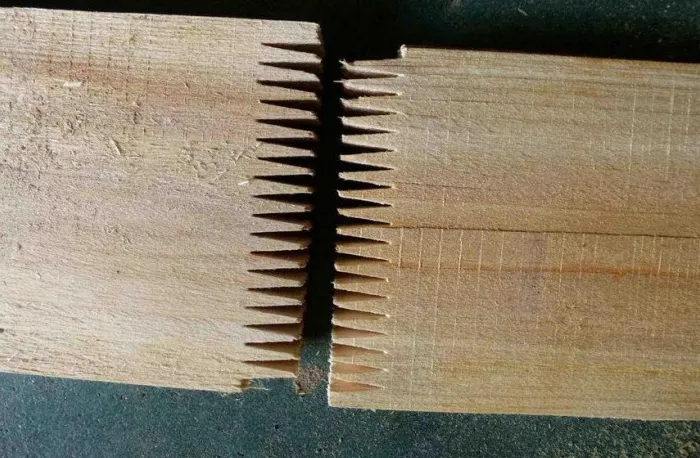

Fabriqué à partir de lames de bois massif assemblées par des joints en forme de doigts.

Pour

- Très respectueux de l'environnement (peu d'adhésif)

- Texture bois naturel

- Bonne résistance et rigidité

- Des performances stables

Cons

- Options d'apparence plus limitées

- Moins flexible que les panneaux stratifiés

Convient pour :

Meubles de salle de bain haut de gamme, meubles d'intérieur et clients qui préfèrent la texture naturelle du bois massif.

3. Quel panneau utiliser pour les armoires de salle de bains ?

Choisir en fonction de taux d'humidité, les habitudes d'entretienet le climat local.

Zones à forte humidité (tropicales, côtières, salles de bains mal ventilées)

Le meilleur : OSB / Panneau multicouche (contreplaqué)

Raison : résistance à l'humidité et stabilité supérieures.

Zones d'humidité modérée

Le meilleur : Panneau de particules (qualité supérieure) / Panneau multicouche

Préférence pour l'esthétique haut de gamme ou le bois massif

Le meilleur : Planche aboutée + finition haut de gamme

Non recommandé pour la salle de bain

✘ Blockboard

✘ MDF (pour les corps de meuble)

4. Tableau comparatif récapitulatif

| Matériau | Force (1-5) | Résistance à l'eau (1-5) | Stabilité (1-5) | Performance environnementale (1-5) | Application recommandée |

|---|---|---|---|---|---|

| Panneau multicouche | 4 | 5 | 4 | 3 | Corps de meuble de salle de bains |

| Panneau de particules | 3 | 3 | 4 | 4 | Corps de l'armoire (stratifié) |

| MDF | 2 | 1 | 2 | 2 | Portes d'armoires uniquement |

| OSB | 5 | 5 | 5 | 4 | Salles de bains à forte humidité |

| Blockboard | 3 | 2 | 3 | 2 | Non recommandé pour les salles de bains |

| Panneau à entures multiples | 4 | 3 | 4 | 5 | Structures d'armoires de première qualité |

5. Conseils finaux et prochaines étapes

Choisir un armoire de toilette commence par le choix de la bonne panel de base.

Un beau design ne peut pas compenser le gauchissement, le gonflement ou l'instabilité structurelle causés par des matériaux inadaptés.

Dans notre prochain article, nous explorerons options de finition de surface pour les armoires de salle de bains - mélamine, panneau UV, placage, finitions de peinture, et plus encore - pour vous aider à prendre une décision complète.

Besoin de recommandations matérielles ou de conseils techniques ?

Si vous souhaitez obtenir des échantillons de panneaux, des comparaisons de performances ou des suggestions d'experts en fonction de votre marché cible ou des conditions climatiques, n'hésitez pas à nous contacter à tout moment.

Nous sommes heureux de vous aider à choisir la solution la plus appropriée. armoire de toilette pour une utilisation à long terme.