При выборе шкаф для ваннойБольшинство людей обращают внимание на его внешний вид, стиль, цвет и дизайн. Но как производитель шкафов для ванной комнаты который видел тысячи инсталляций, я могу с уверенностью сказать: Настоящая долговечность шкафа для ванной комнаты зависит от материала панели, которую вы не видите.

Если бы шкаф был человеком, то фурнитура была бы суставами, дизайн - одеждой, а материал панелей - костями. Понимание "костей" поможет вам выбрать шкаф, который останется стабильным и безопасным даже после многих лет влажности, перепадов температуры и ежедневного использования.

В этом руководстве рассматриваются основные виды деревянных панелей, используемых в шкафах для ванных комнат, - из чего они состоят, как работают и где их лучше всего применять. В конце вы будете точно знать, какой материал подходит для ваших нужд.

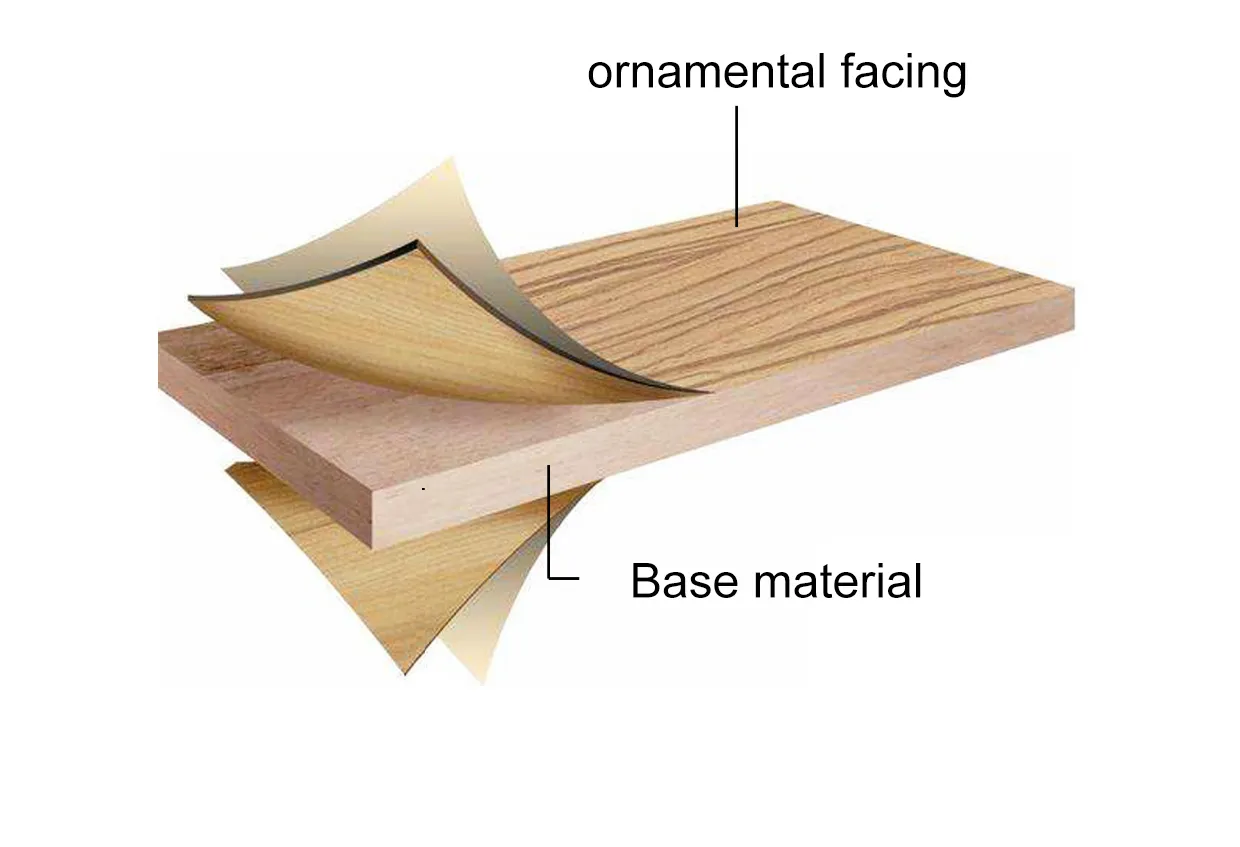

1. Понимание Материалы шкафа: Сердечник + поверхность

Материалы шкафа для ванной комнаты состоят из двух частей:

- Ядро (базовая панель)

- Отделка поверхности

Эта статья посвящена основная панельТак как от него зависит устойчивость, прочность, долговечность и влагостойкость шкафа.

Названия распространенных плит могут быть самыми разными - фанера, многослойная плита, МДФ, OSB, ДСП, блок-плита, меламиновая плита, эко-плита и т.д. Но все они могут быть объединены в несколько основных категорий.

2. Основные типы панелей для шкафов в ванной комнате

2.1 Многослойные панели (фанера / многослойная плита из массива дерева)

Также называется:

- фанера

- многослойная панель из массива дерева

- фанера из твердых пород древесины (HWPW)

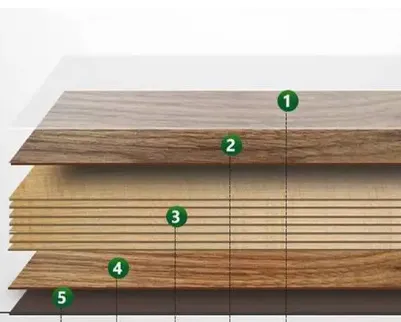

Структура

Как в слоеном торте, деревянные шпоны склеиваются в чередующихся направлениях и скрепляются горячим прессованием.

Эта чередующаяся структура придает панели:

- отличная влагостойкость

- сбалансированная прочность

- стабильная работа

Технические характеристики

Стандартный размер: 1220 × 2440 мм

Обычная толщина: 3 / 5 / 9 / 12 / 15 / 18 мм (для корпусов шкафов обычно используется 18 мм)

Плюсы

- Очень хорошая влагостойкость

- Сильная структурная стабильность

- Высокая прочность фиксации гвоздей

Cons

- Клеи сильно различаются, что влияет на экологические показатели

- Качество в значительной степени зависит от производства

Подходит для:

Корпуса шкафов для ванных комнат, кухонные шкафы и влажная среда.

2.2 ДСП (древесно-стружечная плита / древесно-стружечная плита из массива)

Один из наиболее широко используемых в мире материалов из искусственной древесины.

Структура

Древесная стружка и опилки смешиваются с клеем и прессуются в плиты.

Качество варьируется от очень низкого до очень высокого, в зависимости от:

- качество древесного волокна

- тип клея

- технология прессования

Плюсы

- Хорошая общая производительность

- Стабильная структура, равномерная внутренняя плотность

- Гладкая поверхность, подходящая для ламината

- Хорошая экономическая эффективность

Cons

- Умеренная влагостойкость

- Более низкая способность удерживать гвозди по сравнению с фанерой

- Фрезеровать сложнее

Подходит для:

Корпуса шкафов в помещениях с умеренной влажностью, шкафы с ламинированной поверхностью.

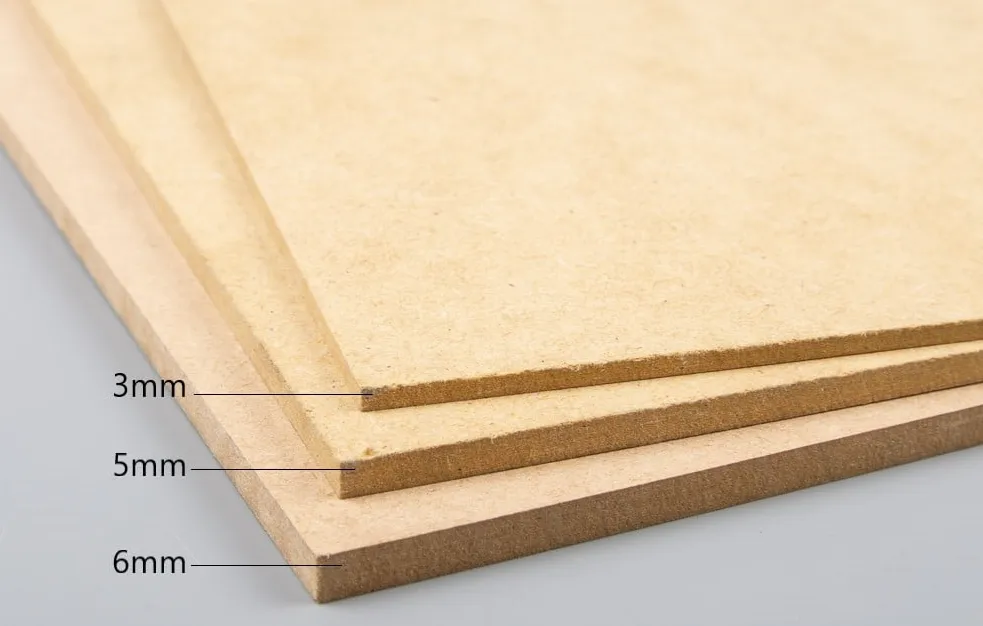

2.3 МДФ (древесноволокнистая плита средней плотности)

Изготовлен из тонко измельченных древесных волокон + повышенное содержание клея.

Плюсы

- Очень гладкая поверхность

- Идеально подходит для окрашенных/резных дверей шкафов

- Легко поддается формовке и обработке

Cons

- Очень плохая влагостойкость

- Разбухает или деформируется при намокании

- Недостаточно прочный для корпусов

- Низкая способность удерживать гвозди

Подходит для:

Шкаф двери (особенно резные или расписные), но не подходит для корпусов.

2.4 ОСП (ориентированно-стружечная плита)

Новое поколение деревянных панелей с направленными планками.

Структура

- Длинные деревянные нити, уложенные в направленном порядке

- Внешние слои ориентированы продольно

- Внутренний слой ориентирован в поперечном направлении

Это обеспечивает исключительную стабильность размеров.

Плюсы

- Отличная влаго- и водонепроницаемость

- Высокая прочность и способность удерживать гвозди

- Очень устойчив к изменениям влажности

- Почти все преимущества фанеры

Cons

- Шероховатая поверхность

- Ограниченные возможности выбора цвета/отделки в большинстве фабрик по производству шкафов на заказ

Подходит для:

Высокая влажность в ванных комнатах, корпусах шкафов и конструктивных элементах.

2.5 Блочная плита (древесно-стружечная плита / столярная плита)

Сердцевина из цельной древесины, ламинированная шпоном.

Плюсы

- Высокая жесткость

- Хорошая фиксация гвоздей

- Легко обрабатывать

- Хорошая звукоизоляция и сохранение тепла

Cons

- Плохая влагостойкость

- Не рекомендуется для кухонь и ванных комнат

- Качество сильно зависит от породы древесины

Подходит для:

Шкафы, двери, перегородки для сухих помещений.не идеально подходит для ванных комнат.

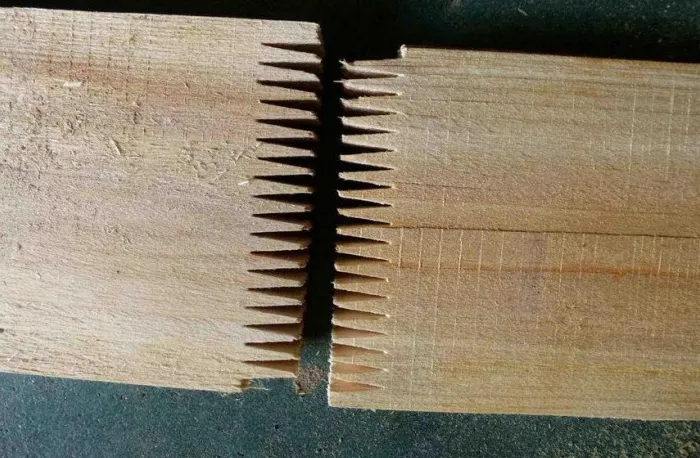

2.6 Плита с пальцевым соединением (плита из цельной древесины)

Изготовлена из цельных деревянных планок, соединенных пальцевыми соединениями.

Плюсы

- Очень экологично (минимум клея)

- Фактура натурального дерева

- Хорошая прочность и жесткость

- Стабильная производительность

Cons

- Более ограниченные возможности внешнего вида

- Не такие гибкие, как ламинированные плиты

Подходит для:

Премиальные шкафы для ванных комнат, мебель для интерьера, а также клиенты, предпочитающие натуральную текстуру массива дерева.

3. Какую панель использовать для шкафов в ванной комнате?

Выбирайте, основываясь на уровень влажности, правила ухода, и местный климат.

Области с высокой влажностью (тропики, прибрежные районы, плохо проветриваемые ванные комнаты)

Лучшее: OSB / многослойные панели (фанера)

Причина: превосходная влагостойкость и стабильность.

Районы с умеренной влажностью

Лучшее: ДСП (высококачественные сорта) / Многослойные панели

Эстетика премиум-класса или предпочтение массива дерева

Лучшее: Доска с пальцевым соединением + отделка премиум-класса

Не рекомендуется для использования в ванной комнате

✘ Блочная доска

✘ МДФ (для корпусов шкафов)

4. Сводная сравнительная таблица

| Материал | Сила (1-5) | Водонепроницаемость (1-5) | Стабильность (1-5) | Экологические показатели (1-5) | Рекомендуемое применение |

|---|---|---|---|---|---|

| Многослойная панель | 4 | 5 | 4 | 3 | Корпус шкафа для ванной комнаты |

| ДСП | 3 | 3 | 4 | 4 | Корпус шкафа (ламинированный) |

| МДФ | 2 | 1 | 2 | 2 | Только дверцы шкафа |

| OSB | 5 | 5 | 5 | 4 | Ванные комнаты с высокой влажностью |

| Блочная доска | 3 | 2 | 3 | 2 | Не рекомендуется для ванных комнат |

| Доска с пальцевым соединением | 4 | 3 | 4 | 5 | Конструкции шкафов премиум-класса |

5. Заключительные рекомендации и дальнейшие шаги

Выбор шкаф для ванной начинается с выбора правильного основная панель.

Красивый дизайн не может компенсировать деформацию, разбухание или структурную нестабильность, вызванную неподходящими материалами.

В нашей следующей статье мы рассмотрим варианты отделки поверхности для шкафов в ванную комнату - меламин, УФ-плита, шпон, лакокрасочные покрытия и многое другое, - чтобы помочь вам в принятии полного решения.

Нужны рекомендации по материалам или техническое руководство?

Если вам нужны образцы панелей, сравнительные характеристики или экспертные предложения с учетом особенностей вашего целевого рынка или климатических условий, обращайтесь к нам в любое время.

Мы будем рады помочь вам выбрать наиболее подходящий шкаф для ванной структура для длительного использования.